This Singapore-invented cooling system needs no water in the data hall

No mechanical pumps, works with air-cooled servers, and scales up to 50kW per rack.

Liquid cooling doesn't require water in the data hall - not if you use this Singapore-invented two-phase rear-door heat exchanger (RDHx).

Last week, I visited the National Supercomputing Centre in Singapore and noted how the KoolLogix system keeps an entire data hall cool at 26°C. As promised, here are more details about this data centre system.

What's two-phase cooling?

Data centre terms sure get confusing at times. In liquid cooling, single-phase cooling means using a coolant that doesn't change state. This is usually water.

Single-phase systems are found in a variety of liquid cooling systems: rear-door heat exchangers, direct-to-chip cooling, and immersion cooling where servers are submerged in a dielectric liquid that doesn't damage electronics.

One downside of water-based liquid cooling systems is the non-zero chance of leaks. In fact, such an incident happened in a Southeast Asia data centre in September.

Two-phase cooling systems use specialised dielectric fluid that undergoes a phase change from liquid to vapour as it absorbs heat. This means no risk of destructive leaks.

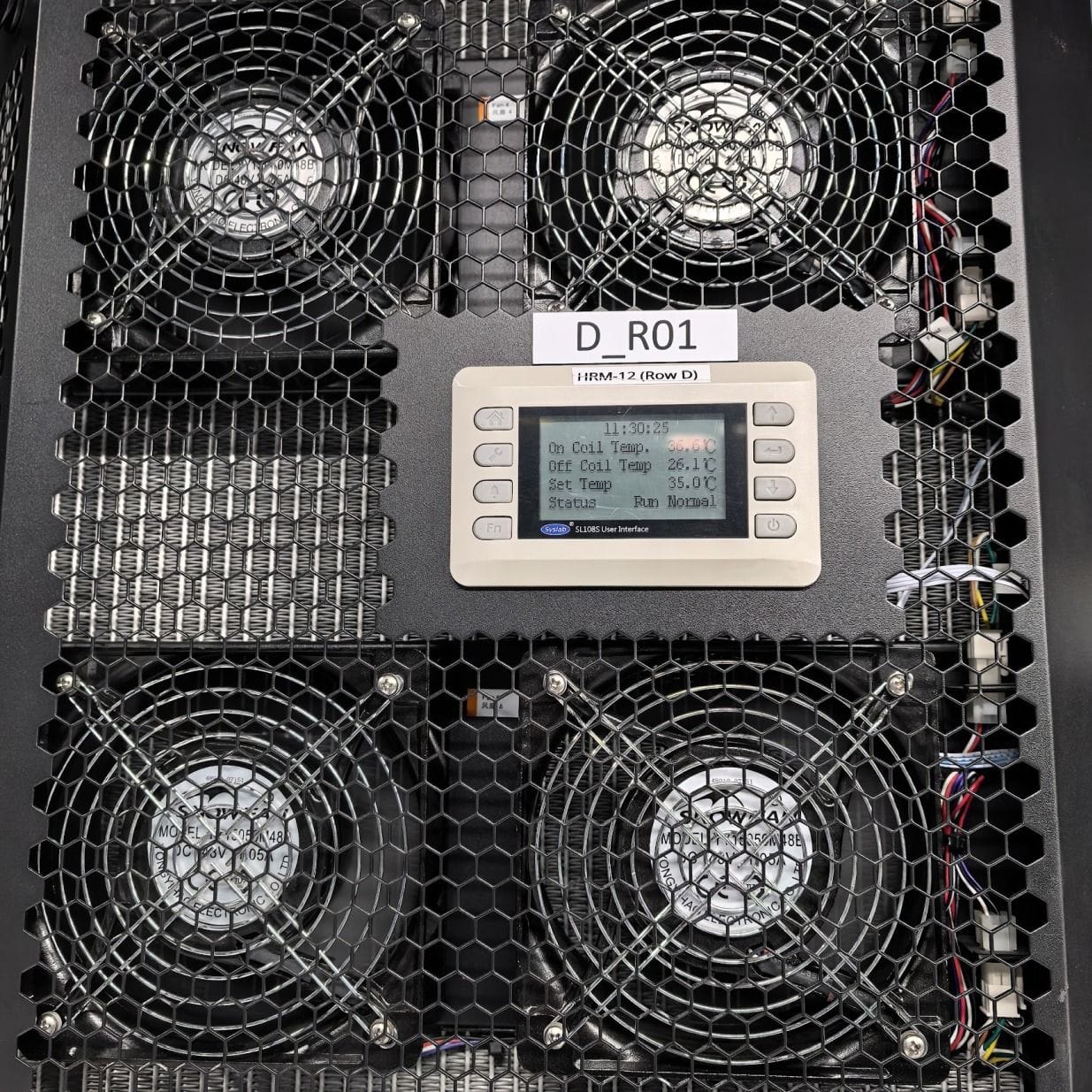

Photo Caption: (Left) A closer look at the HRM-12's controller. (Right) Zooming in on the finned radiator.

Look ma, no pumps

KoolLogix's solution is a rear-door system, attaching to the back of a data centre rack in place of the door. For cooling, it relies on a refrigerant typically used in refrigerators.

Liquid refrigerant flows into each RDHx from an RCU. As they absorb heat, fluid vaporises and is piped via overhead pipes to the RCU which condenses it back to liquid.

Characteristics of the system: no mechanical pumps, works with existing air-cooled servers, and the latest model scales up to 50kW per rack.

The RCU is located on a higher plane away from the data hall and relies on gravity to move the refrigerant. At the NSCC, the RCU taps into chilled water from the building's HVAC.

Photo Caption: (Left) Vaporised refrigerant flows out. (Middle) Gas detector for safety. (Right) The RCU located one floor up.

Pushing the limits

It's worth noting that the original KoolLogix unit was invented a decade ago, at a time when racks were just a few kilowatts each. The ones deployed at NSCC are rated for 20kW per rack.

A newer model has since been released with support for 50kW racks, which is good even for racks crammed with H200 GPU servers.

What do you think of it?