Microsoft's microfluidics breakthrough could enable new, powerful processors. Someday

Seven-year-old chips cool brilliantly in the lab, but don't expect data centre deployments soon.

Microsoft has achieved a breakthrough that cools processors three times better. What is microfluidics, and how could it reshape the data centre?

Last week, Microsoft published a blog post about a breakthrough in microfluidics for cooling CPUs. The announcement quickly spread, sparking a wave of breathless reports. As usual, the reality is more nuanced than the headlines suggest.

Testing on yesterday's chips

The paper on this was actually published in January. Microsoft worked on Intel i7 8700K and Intel i9 9900K CPUs, which were released in 2017 and 2018 respectively. So we're talking about seven-year-old chips here, not the latest generation.

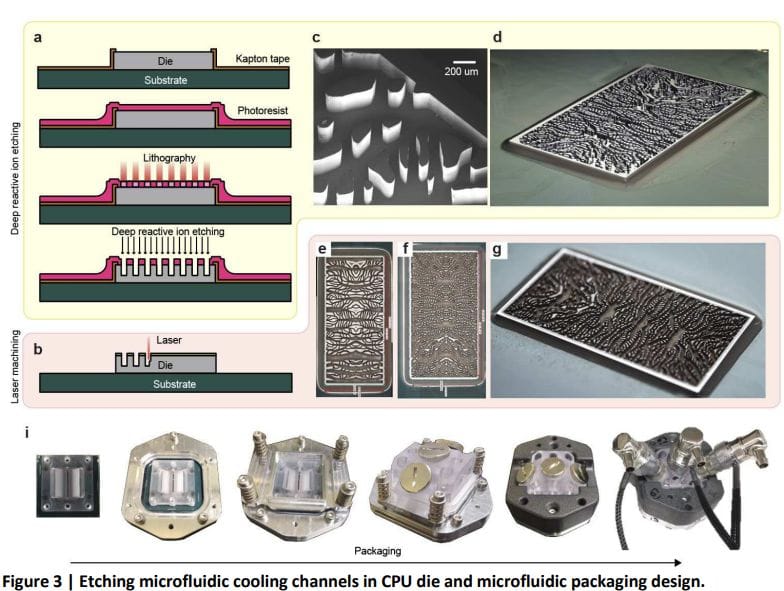

The research team experimented with etching various microfluidic cooling channels into the CPUs, then packaged them complete with built-in manifolds for liquid cooling. According to the paper, the resulting heat removal is significantly better than even immersion cooling, which is simply mind-blowing.

The technical achievement is real. But there's a considerable gap between laboratory success with seven-year-old processors and production deployment in data centres running current workloads. This matters because newer chips are denser, hotter, and more complex.

How it differs from today's cooling

Microfluidics is the science and technology of processing and manipulating extremely small amounts of fluid in micro-scale channels. Think of it as plumbing at a microscopic level.

Today's direct-to-chip liquid cooling systems use cold plates that rest on top of processors. Liquid runs through small channels in these cold plates to absorb heat. Microsoft's approach does away with the cold plate entirely. Instead, liquid runs across microchannels etched directly into the silicon material of the chip itself.

You still need the same data centre infrastructure we have today for DTC liquid cooling. The difference is in efficiency. The very large surface-area-to-volume ratio means more contact between coolant and chip. Etched channels bring liquid closer to the hot transistors where heat is generated. And the small hydraulic diameter drives up the convective coefficient, improving heat transfer.

What this could enable

The benefits are compelling. Microfluidics could support more powerful chips that run hotter than what's possible today. It also allows much higher inlet water temperatures than cold plates, which matters for data centre efficiency and cost.

The really interesting possibility is stacked, three-dimensional processors. Current cooling methods can't handle the heat density of 3D chips effectively. Microfluidics could potentially channel water through the chip stack itself, opening up entirely new processor architectures.

Microsoft experimented with chips from seven years ago, and the paper itself noted that long-term reliability must first be investigated. In my view, this means we are still very far from the deployment of microfluidics-enabled processors in the data centre.

The breakthrough is real, but the path from laboratory to production involves solving problems that haven't even been fully identified yet. Validating the technology on the latest processors, ensuring reliability, and getting chip makers to incorporate it at the foundry, are just some of the steps that are needed.