Inside Malaysia's first data centre water reclamation plant

As demand for data centres exploded in Johor, so did the need for sustainable water solutions.

I visited Bridge Data Centres' state-of-the-art water reclamation plant in Johor today, where the first facility in Malaysia produces treated wastewater for its sprawling 200MW MY-07 data centre campus.

For the first time I realised that water treatment isn't a single-step process; there are multiple steps involved.

The story of water

As demand for data centres exploded in Johor, so did the demand for water to cool power-hungry servers. But water is precious. How do we manage this precious resource in a sustainable manner?

That's where water reclamation comes in. Instead of discharging the non-potable treated effluent from sewage treatment plants (STP), why not further process it into high-grade water for data centres?

And that was how the Bridge Data Centres Water Reclamation Plant (WRP) at Ulu Tiram came about. It is currently the only such WRP that processes water for data centre use.

Initial treatment

Photo Captions: (Left) Anoxic tank under this trapdoor. (Right) Oxidation tank.

Effluent from nearby STPs is piped into the WRP for processing. Initial key steps include an anoxic tank that removes nitrogen from water, and an oxidation tank where bacteria break down organic matter.

Together, they remove nitrogen, phosphorus, and organic pollutants to achieve high pollutant removal standards.

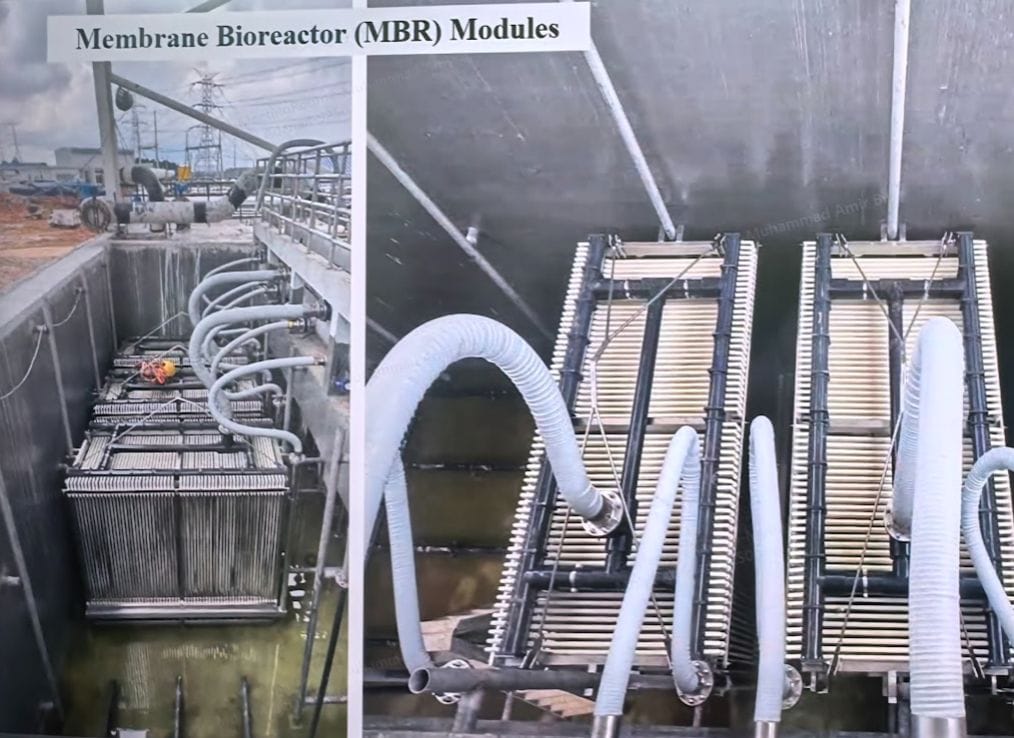

Membrane Bioreactor (MBR)

Photo Captions: (Left) Membrane bioreactor in operation. (Middle) Membrane bioreactor before deployment. (Right) Incoming treated wastewater for Membrane bioreactor processing.

Next, the MBR uses membranes to remove suspended solids, bacteria, and even some pathogens to produce high-quality effluent.

In the photo on the right, you can see the MBR in operation. Water is suctioned through the membranes, which retain pollutants.

Reverse Osmosis (RO)

Photo Captions: (Left) Pressure vessels containing membrane elements. (Right) View of a reverse osmosis stage.

Finally, RO uses high pressure to force water through an extremely fine membrane to remove dissolved and microscopic contaminants.

These are spiral-wound membranes packed tightly inside a long tube. As I wrote previously, the ones in Bridge Data Centres' WRP are made by Suntar International Group, a Singapore-headquartered firm.

Also, Bridge Data Centre's WRP uses three passes. Singapore's NEWater is produced from two passes of RO, though the latter is paired with other processes.

The future of data centres?

Today, I also learned that there are processes to clean both MBR and RO membranes to extend their lifespans, which I understand to be measured in years. This is quite different from my previously flawed understanding that they are discarded regularly.

And as shared by Lye Yit Tho on a panel discussion at DCW Asia, if incoming treated wastewater quality is good, the team may elect to skip the RO pass.

There are some other steps I didn't go into due to space. Suffice to say, the WRP produces high-grade water that goes into storage tanks for data centre use.

Do you see this as the future of data centres, with a focus on sustainability and water treatment done in-house? What do you think?