Cool under pressure: Liquid-to-liquid vs liquid-to-air

Greenfield or retrofit, here's how to support your direct-to-chip deployment.

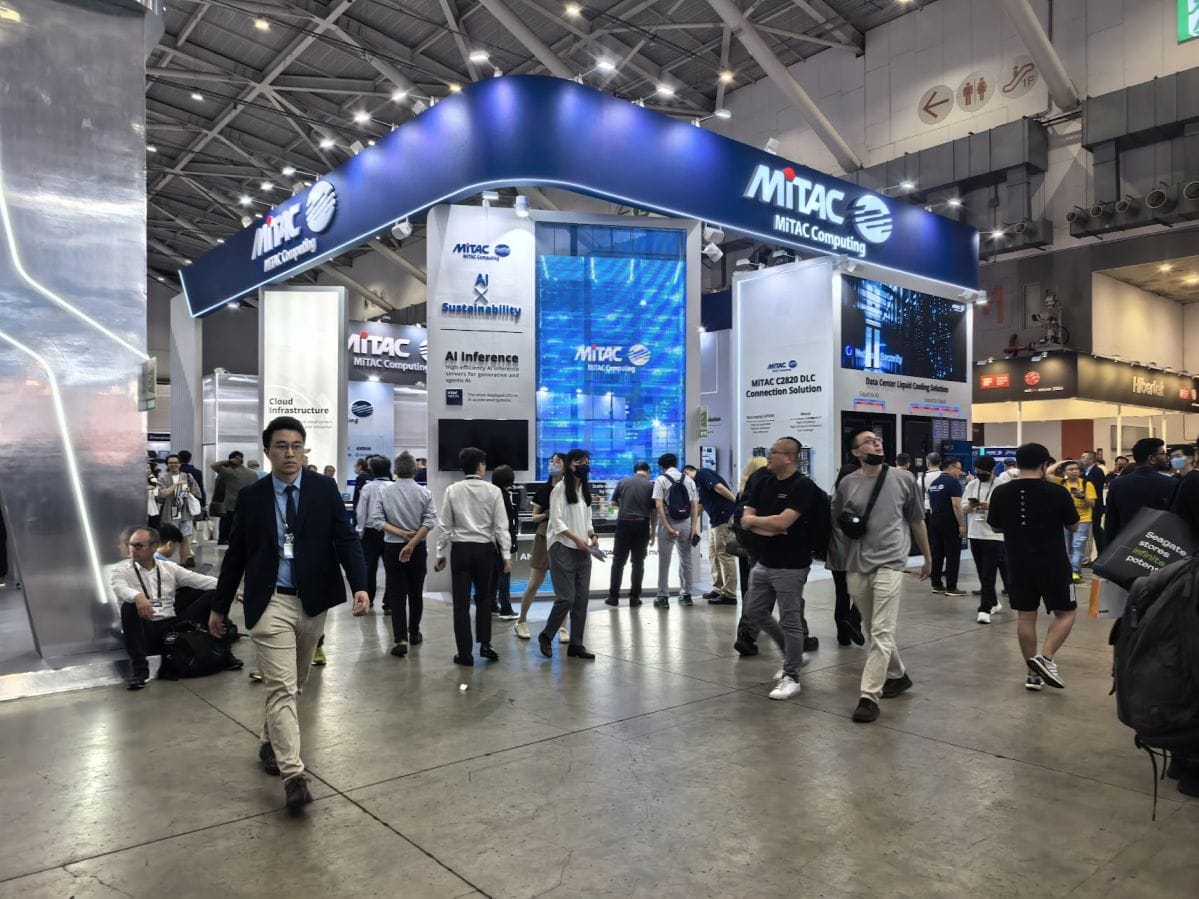

Liquid cooling is the rage at Computex as AI takes off. But what's the difference between liquid-to-liquid and liquid-to-air cooling? Read on.

The data centre ecosystem is working overtime to support direct-to-chip (DTC) cooling, where liquid is piped into individual servers for cooling.

But you can't just roll your new, very costly AI racks into your data centre, plug them in and power them on.

You must first:

- Speak to the data centre operator.

- Provision cooling capacity.

- Install new equipment.

Honey, we need to talk

Enterprises or cloud service providers (CSP) that want to roll out liquid-cooled servers must first check with their data centre operators.

This is to verify that adequate cooling capacity is available, and for them to install the requisite plumbing and equipment.

Making liquid cooling work

Below are two common deployment scenarios for DTC liquid cooling in the data centre.

Say 'hello' to the CDU

The most common suggestion is to deploy a CDU, or Coolant Distribution Unit. This takes in chilled water to cool the secondary loop that goes to the servers.

It looks like this:

Chillers/Cooling Towers

🔄 (Primary loop)

CDU

🔄 (Secondary/closed loop)

GPU servers

The latest CDUs are very powerful and can cool multiple GPU racks.

Sorry, we can't support CDUs

While a CDU deployment is optimal, there are situations where liquid cooling cannot be supported for various reasons.

- Existing deployment.

- Hot welding works prohibited.

- Old pipes don't offer adequate flow rates.

Fortunately, you don't have to give up on your DTC plan thanks to liquid-to-air solutions out there, which take the place of CDUs.

It looks like this:

Liquid-to-air cooling unit

🔄 (Closed loop)

GPU servers.

The MiTAC cooling unit in the photo is no weakling and can do 100kW - this is a cooling machine jam-packed with fans and heat exchangers.

According to MiTAC's James Peng, some situations might call for 2x units (at 50% each) to cool a 100kW rack; because each unit can gulp in so much air, it can leave servers without enough air-cooling.

Other considerations

Of course, this explanation vastly simplifies the complexity of rolling out liquid cooling in the data centre.

CSP must consider everything:

- Customised servers.

- Integration design.

- Deployment.

- Testing.

- Monitoring.

Much like no two data centres are the same, I expect liquid cooling deployments to be similarly unique.

And oh, James tells me MiTAC can do everything end-to-end.

Have you worked with liquid cooling? What's your biggest headache?