The case for two-phase DTC liquid cooling in Southeast Asia

Two-phase direct-to-chip cooling promises 97% free cooling in tropical Singapore.

AI data centres are pushing cooling limits. Could two-phase direct-to-chip (DTC) liquid cooling be the breakthrough? Here's how it works.

Liquid cooling today

I've written often about liquid cooling in data centres, highlighting its various pros and cons. The three key types of liquid cooling are rear door coolers (RDC) with chilled water to each rack, direct-to-chip (DTC) with chilled water to CPUs/GPUs, and immersion cooling in dielectric liquid.

In general, liquid cooling is not required for non-AI workloads, given that they average just 8kW per rack as of 2024, according to Uptime Institute. However, AI data centres or mixed deployments will definitely benefit from it, which makes liquid cooling important for data centres in the future.

In July, Lucas Beran presented at OCP's Southeast Asia Tech Day in Singapore, where he talked about pumped two-phase DTC cooling.

Citing an analysis for prospective customers in Singapore, he says that traditional single-phase DTC can offer free cooling 24% of the year. With P2P DTC, however, Lucas says it's possible to achieve free cooling an astounding 97% of the year in tropical conditions.

While free cooling is not the same as free-air cooling, one can assume substantial energy savings, which is what Singapore's Green Data Centre Roadmap is about.

How does it work?

What is P2P DTC cooling? I dug into an OCP white paper titled "Pumped 2P refrigerant-based direct liquid cooling (DLC) Technology for next generation AI Clusters with high TDP accelerators" released in February to learn more.

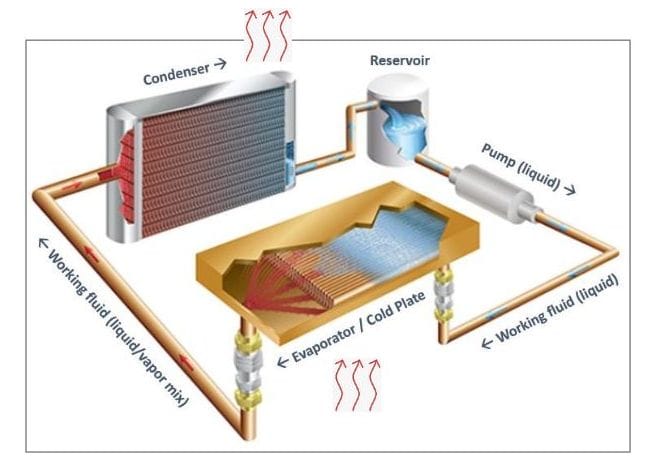

In single-phase DTC, water flows through cold plates to absorb heat. In P2P DTC, a dielectric refrigerant undergoes a phase change inside the cold plate, boiling from liquid to vapour as it absorbs heat from CPUs or GPUs.

As with single-phase systems, refrigerant is circulated via manifolds from a CDU. Vapour returns to the CDU, where it's condensed back into liquid and recirculated. This phase-change process has a much higher heat transfer coefficient.

A snapshot of the benefits: better heat transfer performance, no danger of damage from leaks, a rich HVAC ecosystem to draw from, minimal risks of corrosion or bio growth, and better TCO by using warmer chilled water. I believe the ability to use more free cooling is related to the higher inlet temperature that P2P DTC can accept.

The PFAS problem

One significant drawback: many refrigerants fall under PFAS, so-called "forever chemicals" that are increasingly under scrutiny. This isn't a minor concern. Europe is moving towards PFAS restrictions, and other regions may follow.

On the other hand, a 97% free cooling figure in tropical conditions sounds phenomenal, especially given the sustainability goals of countries such as Singapore. Which means P2P DTC represents an intriguing possibility worth watching.

What do you think of P2P DTC?